News and Innovations

April 2024

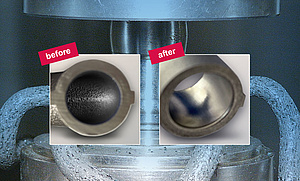

Post-processing of additively manufactured components

With additively manufactured components (rapid prototyping or 3D printing), there is often a need to improve the surface quality. With the help of abrasive flow machining, the surfaces in internal channels and complex component geometries in particular can be processed and excellent results achieved.

November 2023

Spare parts even after years

Are your abrasive flow machines still doing their job safely and tirelessly for many years? Have your cleaning systems also been in use for many years thanks to their robustness? With expert maintenance, older machines will continue to function perfectly and reliably even after decades.

July 2023

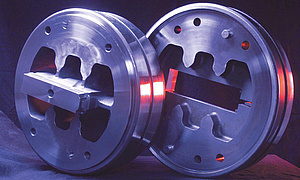

Efficient processing of extrusion dies

Extrusion dies must be reworked and optimized by skilled professionals in laborious work by hand. These works increasingly result in higher tool price. The use of MicroStream abrasive flow machining leads to a significant cost reduction while improving the quality of the end product.

April 2023

AFM-Medium streamer – the liquid file

The central tool for the mechanical removal process of Micro Stream abrasive flow machining is the streamer. It is individually adapted to the material to be processed, the component geometry and the desired surface quality. This supports the process decisively, reduces machining times and delivers the best surface qualities.

November/2022

Modernize your control system now!

Industry 4.0 allows for a sharp leap in productivity and profits. Those who use this development create significant competitive advantages for themselves and their customers. Your control system has a lot of intelligence and potential, too. In collaboration with Pütz Prozessautomatisierung GmbH we are today once more offering you the chance to adapt your control system to the technology of the future.

April/2022

Test processing of individual pieces and prototypes

Are your components as unique as you are? Do your workpieces feature a complex geometry, unusual material, extraordinary machining task or simply require surface improvement? Take advantage of our test and development departmentwith many years of experience in abrasive flow machining and vibratory finishing. Send us your special post-processing task along with sample parts and drawings. Together we can create the perfect machining process for your individual pieces and prototypes.

November/2021

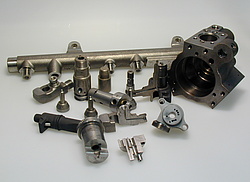

Which processing tasks can we solve for you?

Whether valve bodies, gear components, turbine blades, dies or 3D components – every workpiece requires an individual solution for the processing of its surfaces.

We are your partner for abrasive flow machining processes covering everything from analysis, subcontracting to the implementation of processes at your company location.

July/2021

We optimise cleaning and electroplating processes!

Micro + Hega Surfaces develops and manufactures customised cleaning systems to your specific requirements. Thanks to our extensive manufacturing and production programme and more than 70 years of experience in development, design and manufacture, Micro + Hega Surfaces is able to meet the most diverse customer requirements.

The results are lasting and sustainable superior cleaning results.

01/2021

Comfort Line – permanently slimmer!

MicroStream abrasive flow machining systems assist you in the grinding and deburring of difficult to reach internal bores as well as the rounding of edges or the polishing of milled, turned or cast components – and all completely independent of their geometric shapes.

Our products stand forhighest quality and reliability, and we are constantly working to improve them for your benefit. OurComfort Line therefore now also comes in aspace-saving design.

03/2020

Do you already know our Streamer?

Did you know that the optimal selection of the abrasive medium, which we call the Streamer, contributes significantly to the success of abrasive flow machining?

The use of a Streamer that is adapted to your processing task provides decisive support for your process, reduces processing times and delivers the best surface qualities.

02/2020

Expansion thanks to reduction?

Expansion and reduction are not mutually exclusive in this case. By installing our reducing kit, you decrease the cylinder diameter of your abrasive flow machine and thereby expand your processing spectrum. As a result, you are perfectly prepared for both test processing as well as serial production, for small, delicate and large components - all with one machine.

learn more »»

01/2020

We are your partner for contract manufacturing

For components with traditional production methods, and for additively manufactured components in particular, there is often a need to significantly improve the surface quality, especially if they have hard to reach, internal surfaces. We would be happy to process your workpieces as a service provider at our contract manufacturing site in Freiberg am Neckar.

See the quality of our machining for yourself, and the opportunities it opens up for your individual workpieces. We are happy to create an initial feasibility analysis for your components based on drawings.

03/2019

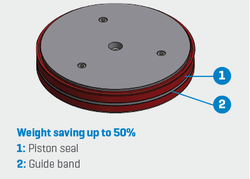

Optimization of medium piston in the grinding process of inside surfaces

With our abrasive flow machining process you can achieve significant improvements in the surface quality of your processed workpieces. The new, modular medium pistons from Micro Surfaces minimise the number of spare part replacements you will have to make in future. In the event that a sealing edge wears out, only the piston seal and, after even longer run times, the guide band need to be replaced.

02/2019

More powerful hydraulic aggregate and optimised software

Perfect coordination of all components forms the basis for first-class product quality. Our systems now have a more powerful hydraulic aggregate. In conjunction with optimised software this leads to an even more stable process and thus to the best grinding results.

01/2019

The new heating/cooling system with anti-condensation coating

The temperature of the STREAMER abrasive medium has a high impact on the processing quality. We have developed a significantly improved heating/cooling system and redesigned the heat exchanger. These measures ensure that the medium remains at a consistent temperature. Moreover, an additional anti-condensation coating increases the service life of the Streamer.

01/2018

Optimization of medium piston in the grinding process of inside surfaces

In the future we want to send you regular information under the heading on current topics, innovations and projects for Micro Surfaces.